Beschreibung

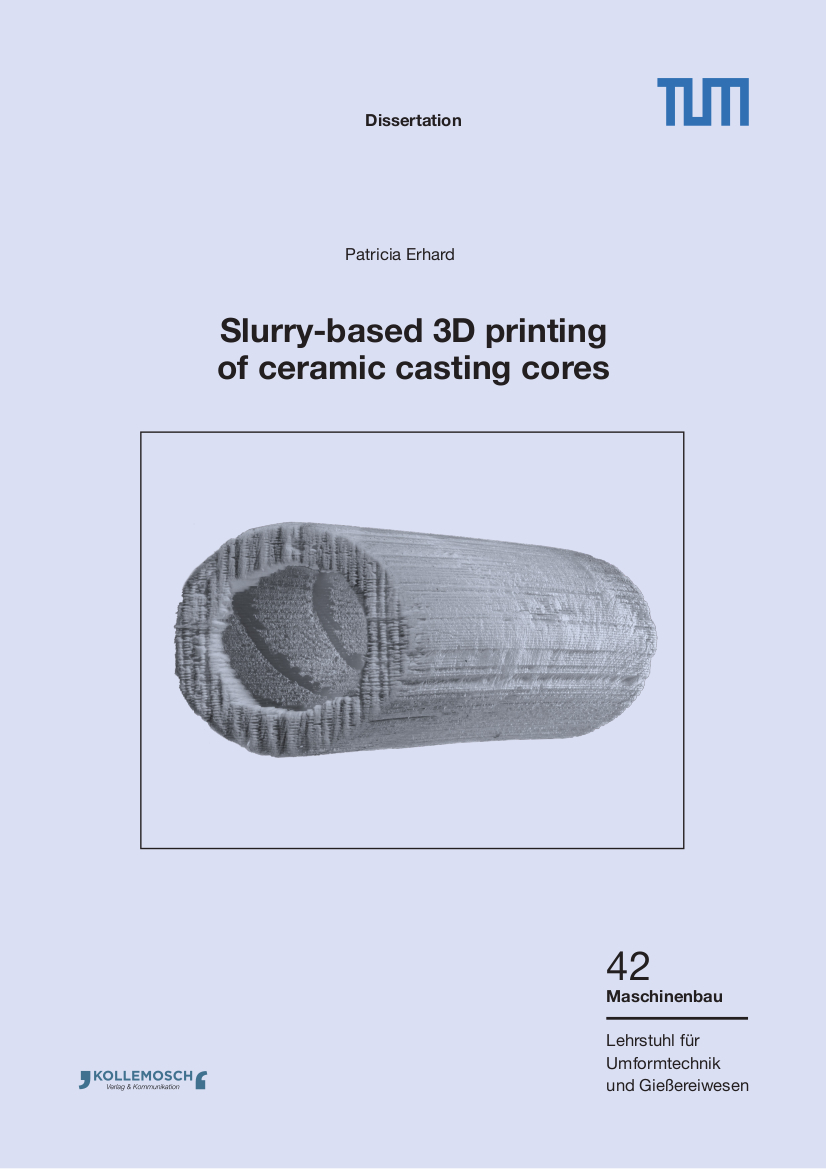

Binder jetting is a highly productive additive manufacturing process in which particulate material is applied to a build platform in layers and selectively printed with a binder. This work deals with processing ceramic slurry instead of dry, flowable quartz sand commonly used in the foundry industry. A slurry-based 3D printing test setup enabling tailored process control was developed. The layer-wise drying configuration’s influence on ceramic specimens‘ material properties was studied systematically. Compared to powder-based 3D printing with sand, the average roughness depths could be reduced by ~ 90 % to 1.2 µm. In a shrinkage-free sintering process, the final strength was adjusted to approximately 10 times higher with 25 MPa. Improved material properties were achieved with longer drying periods. It has been shown that by incorporating predetermined breaking lines into the internal geometry of hollow cast core structures, the stresses arising during shrinkage of the solidifying metal alone can induce core failure. Mechanical decoring of slurry-based 3D printed ceramic casting cores can thus be envisaged for filigree core geometries required for, e.g., efficient close-contour cooling structures in high-performance cast components.

Binder jetting is a highly productive additive manufacturing process in which particulate material is applied to a build platform in layers and selectively printed with a binder. This work deals with processing ceramic slurry instead of dry, flowable quartz sand commonly used in the foundry industry. A slurry-based 3D printing test setup enabling tailored process control was developed. The layer-wise drying configuration’s influence on ceramic specimens‘ material properties was studied systematically. Compared to powder-based 3D printing with sand, the average roughness depths could be reduced by ~ 90 % to 1.2 µm. In a shrinkage-free sintering process, the final strength was adjusted to approximately 10 times higher with 25 MPa. Improved material properties were achieved with longer drying periods. It has been shown that by incorporating predetermined breaking lines into the internal geometry of hollow cast core structures, the stresses arising during shrinkage of the solidifying metal alone can induce core failure. Mechanical decoring of slurry-based 3D printed ceramic casting cores can thus be envisaged for filigree core geometries required for, e.g., efficient close-contour cooling structures in high-performance cast components.

Slurry-based 3D printing of ceramic casting cores

Autorin: Patricia Erhard

Seiten: 172 – bebildert

Bindung: Broschiert

Sprache: Englisch

ISBN: 978-3-9820746-6-5

Erscheinungsdatum: 10. August 2023

Preis € 39,00 inkl. Versand innerhalb Deutschlands.